The brandnew MGISTP-7000 is a high-throughput automated sample transfer processing system - up to 7'000 samples/day!

It integrates tube decapping, tube recapping, barcode identification, automated liquid transfer and negative pressure protection. It decreases steps and delivers the quality and reliability you expect. You can transfer 192 samples from screw cap transport tubes or plain tubes to 96-Well Microplates in 40 minutes.

Two channel independent pipette heads, offer a volume range from l0uL to l000uL. Enabling flexibility efficiency, safety and process quality. All the steps are integrated in a closed and negative pressure system. Two HEPA-filtration and one UV light ensure a safer working environment for both liquid transfer and lab technicians.

Description

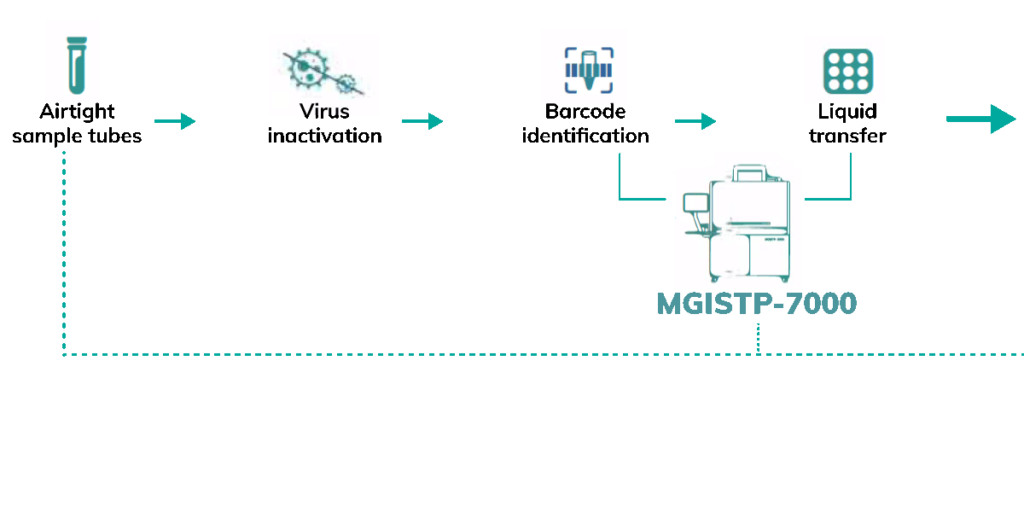

- Automated: Load airtight sample tubes into a standard rack. Just a single-click, it will finish the tedious sample pre-analytical steps for you.

- Powerful: Design for laboratories that require high productivity. Transfer 192 samples from screw cap transport tubes to 96-Well Microplates in 40 minutes.

- Safe: Two HEPA-filtration and one UV light ensure a safer working environment for both liquid transfer and lab technicians.

- High Reliability: Barcode information can be automatically stored and transferred to ZLIMS system, providing information traceability.

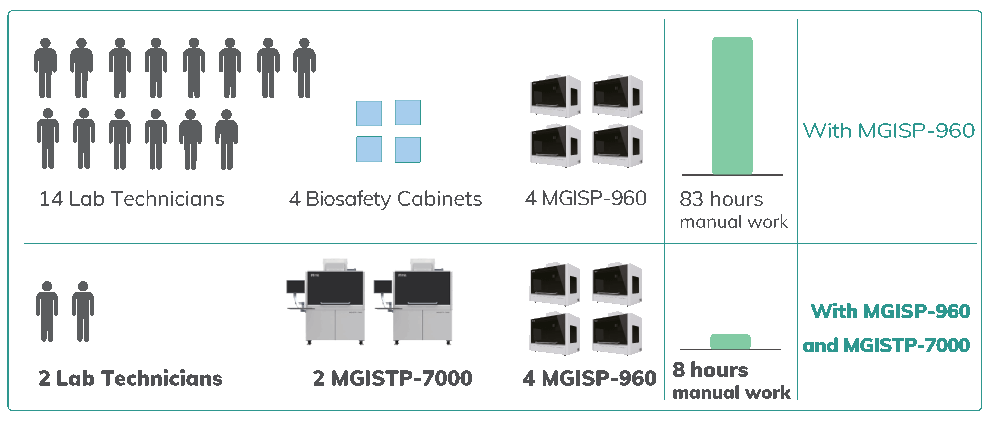

10’000 samples per day

Sample Preparation and High Productivity

MGISTP-7000 is designed for laboratories that require high productivity. You can transfer 192 clinical samples from screw cap transport tubes to 96-Well Microplates in 40 minutes. For very high throughput testing operations, you just need to add multiple downstream nucleic acid extraction systems. If you own a standard liquid transfer instrument, high-throughput MGISTP-7000 can maximize your PCR testing efficiency.

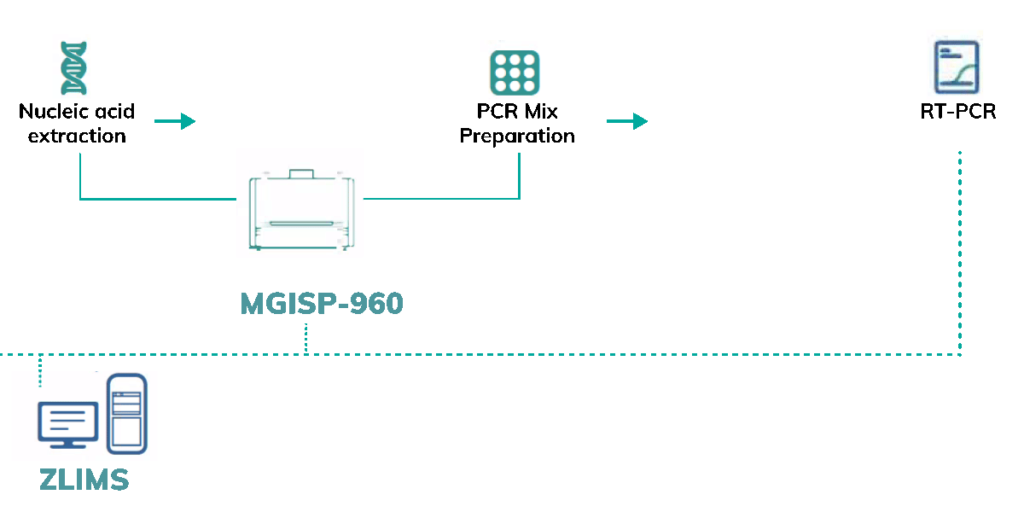

Powerful and User-friendly

An easy-to-use software platform, allows effortless set-up and quick operation. Just a single-click, it will finish the tedious sample pre-analytical steps for you.

Flexible automation upgrade solution – MGISTP-7000 can connect with ZLIMS system, which is a powerful laboratory management software, helping you integrate various third part instruments, such as RT-PCR system and nucleic acid extraction system.

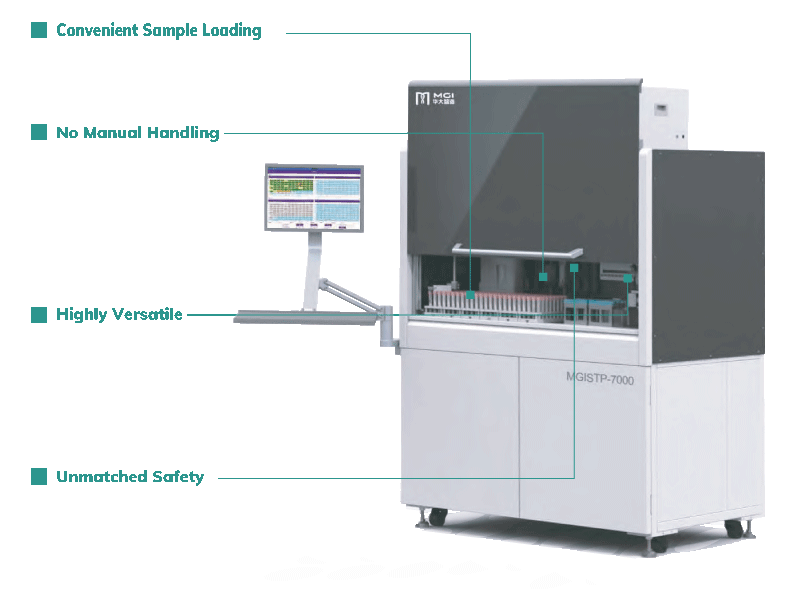

Convenient Sample Loading

Airtight sample tubes in a standard rack reduces exposure to samples. The system can run up to 7000 samples per day.

No Manual Handling

One Epson robot arm, four recap and de-cap modules, four barcode scanners, and two channel-independent pipette heads. Barcode information can be automatically stored and transferred to any LIMS system.

Highly Versatile

Two pipetting channels allow free configuration for volume range and disposable tips. The samples can be rapidly transfered into an ANSI/SBS 96-well microplates without manual pipetting errors, supporting a wide variety of automation laboratory equipment.

Unmatched Safety

Re-cap sample tubes after liquid transfer to minimize sample exposure and prevent cross contamination. All samples will be returned to their original location. Provide HEPA-filtration and UV light to ensure a safer operation envrionment.

Specifications

| Functions |

Integrate multiple functions, including decapping, recapping, barcode identification, automated liquid transfer, HEPA-filtration and negative pressure protection |

| Pipetting Method |

Based on the principle of air displacement, with disposable tips |

| Volume Range |

10 µL-1000 µL |

| CV |

10 µL:<5%; 100 µL:<2% 1000 µL:<7% |

| Accuracy |

10 µL: <±70%; 700 µL: <±5% 1000 µL: <±2% |

| Robot Arm Accuracy |

X-Y-Z: ±0.1mm |

| Barcode Scanner |

4 1D Scanner Sensors |

| Protection |

UV Light: 36W Supply/Exhaust Air Filter: ISO 5, HEPA 99.995% at 0.3µm, Negative Pressure System |

| Tube Compatibility |

Universal fit. Excellent fit on 5mL and 70mL Transport tube with screw cap. |

| Dimensions | Weight |

7470mm(W)960mm(D)2700mm(H) 550 kg |

| Operating Environment |

Temperature: 19°C-25°C Relative Humidity: 20% RH -80% RH, Non-condensing Atmospheric Pressure: 80 kPa – 106 kPa |